Jaw crusher

Usage and application :

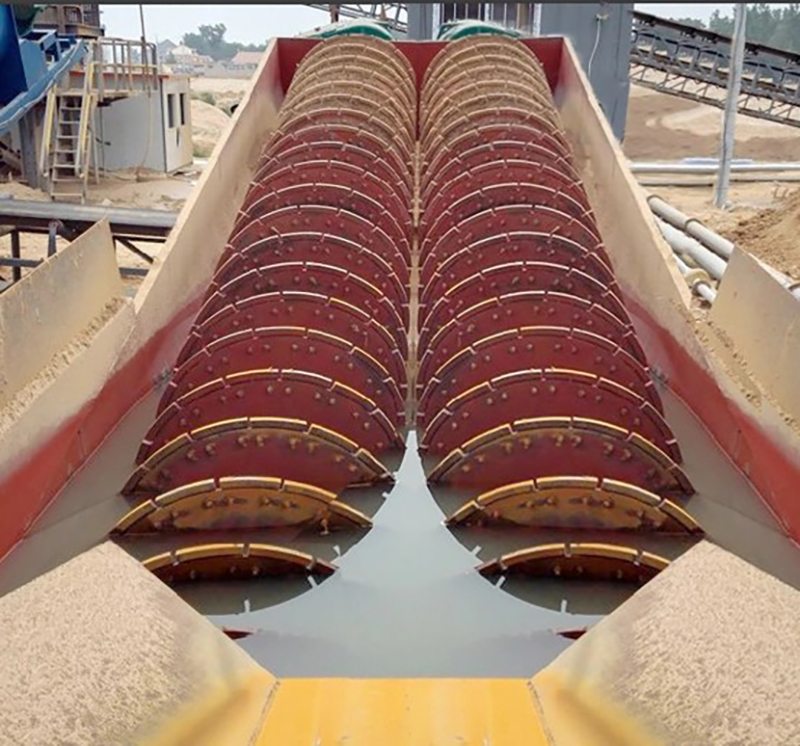

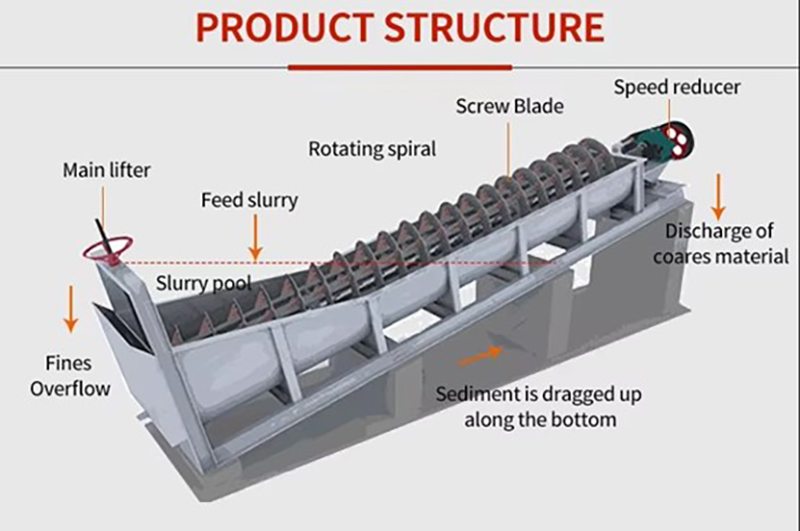

The high weir classifier is a common equipment in the grinding cycle. It is usually combined with a ball mill to divert ore in a closed circuit, or it is used to classify the size of the pulp in the metal beneficiation process,it is suitable for coarse-grained classification, and can also be used in desliming and dehydration operation.It also has the advantages of stable operation and adjustable classification granularity.

Working principle:

Classifier is mainly composed of rotating device, helix, tank, lifting mechanism, lower support (bearing) and ore discharge valve.When working, classifier is based on the principle that the size of solid particles is different, the specific gravity is different, and the settling speed in the miscellany liquid is different, and the fine ore particles float in the water into overflow Coarse ore sinks to the bottom of the tank.

The pulp from the tank side of the central inlet into the U-shaped groove, with the spiral of low speed rotation and continuous stirring pulp, so that most of the light and fine particles suspended in the above, overflow weir overflow, known as overflow products;The coarse and heavy particles will settle with the bottom of the chute, and are pushed to the top of the chute by the spiral blade and discharged, and the dehydration will be completed in the conveying process at the same time.If the settling sand enters the grinding mill through the chute, the settling sand enters the grinding mill is returned sand.

Features:

1.Controllable granularity

By adjusting the height of the weir (the height of the liquid level of the ore slurry), the particle size of the classification

can be adjusted to effectively prevent excessively large particles and sieve residues in the product.

2.High output and low consumption

Frequency conversion control technology, high degree of automation, under the same processing capacity, the energy consumption is 50% lower than other classification equipment, and the output is 50% higher under the same energy consumption.

3. Low maintenance rate

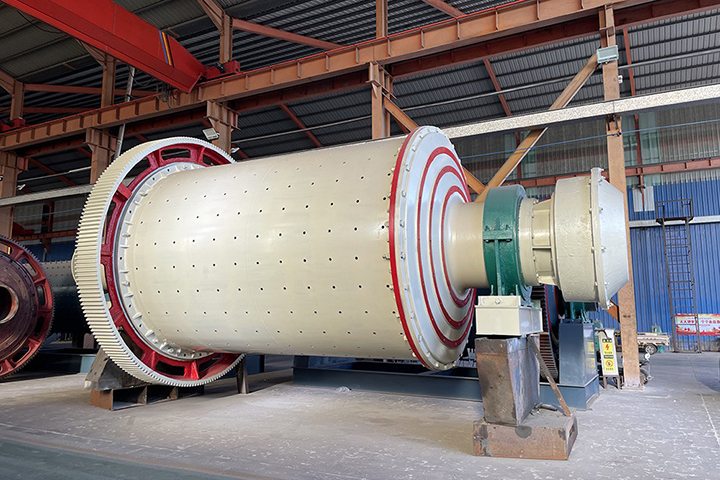

Cancel the configuration of the big spoon head of the ball mill, reduce the maintenance rate and slow down the unbalanced impact on the large and small gears of the ball mill.

4. High quality parts

The base of the machine is made of channel steel, and the body is welded with steel plates, which is wear-resistant and durable, and can be configured with a special hierarchical structure according to different special requirements.