Jaw crusher

Usage and application:

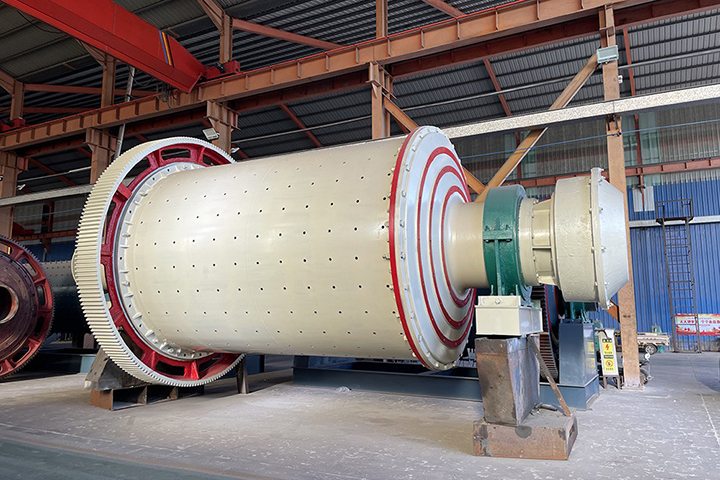

Rod Mill is a grinding machine similar to a ball mill. The obvious difference between the two is the grinding medium. Rod mill is named for the medium of the steel rod. Rod mill can be used for grinding various metal ore and non-metal ore. In some cases, rod mill is also called rod type sand making machine, which is mostly used for making sand.

1. For re-election or magnetic separation equipment of tungsten-tin ore and other rare metal ores, to prevent damage caused by excessive grinding, a rod mill is often used.

2. When using a two-stage grinding process, if the first part is milled from 20-6mm to 3-1mm, the rod mill is used as the first part of the grinding equipment. More productive capacity and higher efficiency.

3.In some cases, it can be used to replace the short cone crusher for fine crushing. The configuration is simpler and the cost is low, which can simplify the dust removal in the crushing workshop.

Working principle:

Rod mill drive by the motor through reducer gear reducer and the surrounding low-speed synchronous motor drive or directly through the surrounding large gear reduction drive,the drive cylinder rotation.Cylindrical body with an appropriate grinding media - steel rods.Grinding media in the role of centrifugal force and friction,has been elevated to a certain height,was thrown down or drain off the state down.Wash milled material from the mine mouth into the cylinder continuously inside the movement shattered grinding media,and through the overflow and continuous power to the mine product from the plane to the next section of processes operating.

Features:

1. More uniform discharge particle size: The rod mill replaces the traditional ball mill's surface contact with linear contact, which is beneficial for the crushing of coarse particles. The output product has a more uniform particle size distribution, ranging from 0.147 to 0.833mm, with less over-crushing.

2. Power saving: It saves more than 40% power compared to traditional equipment, resulting in higher working efficiency and lower electricity consumption, reducing your operational costs.

3. Adjustable discharge fineness:There is a fineness control device and a discharging screening device inside the rod mill, which can be adjusted according to the user's needs to ensure the size of the grinding particles.

4. Good sealing performance: It can prevent dust and noise pollution to the environment, promoting green and environmentally friendly operations.