Jaw crusher

Usage and Application

This series of jaw crushers (jaw crushers) have the characteristics of large crushing ratio, uniform product particle size, simple structure, reliable operation, easy maintenance, and economical operating costs. Jaw crusher is widely used in mining, building materials, chemical industry, metallurgy and other industries. It can perform coarse and medium crushing operations on various ores, rocks and other materials with a compressive strength of not more than 320MPa. It is an ideal choice for ore crusher, coal gangue crusher, etc. The first choice equipment for crushing ore materials.

Working Principle

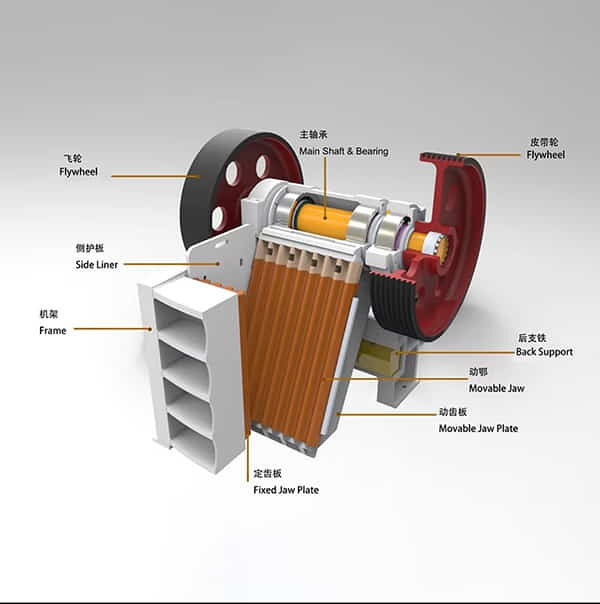

It is mainly composed of a frame, an eccentric shaft, a large pulley, a flywheel, a movable jaw, a side guard plate, an elbow plate, a backseat of the elbow plate, a gap adjusting screw, a return spring, a fixed jaw plate, a movable jaw plate, and other components.

The belt and belt pulley are driven by a motor, and the movable jaw moves up and down via eccentric shaft. The angle between fixed jaw and movable jaw becomes smaller when the moving jaw runs down, then the materials are crushed into pieces. It becomes bigger when the movable jaw runs up. The movable jaw plate leaves the fixed jaw plate under the action of tension rod and spring, then the end products come out from the crushing cavity.

Features:

1. Simple structure, convenient maintenance;

2. High crushing ratio, even output granularity;

3. High reliability, low investment;

4. Low noise, less dust.