Jaw crusher

Usage and application:

Cement rotary kiln is a kind of that specializes in processing cement. The cement rotary kiln currently produced is mainly for cement clinker dry and wet production lines.

Working principle:

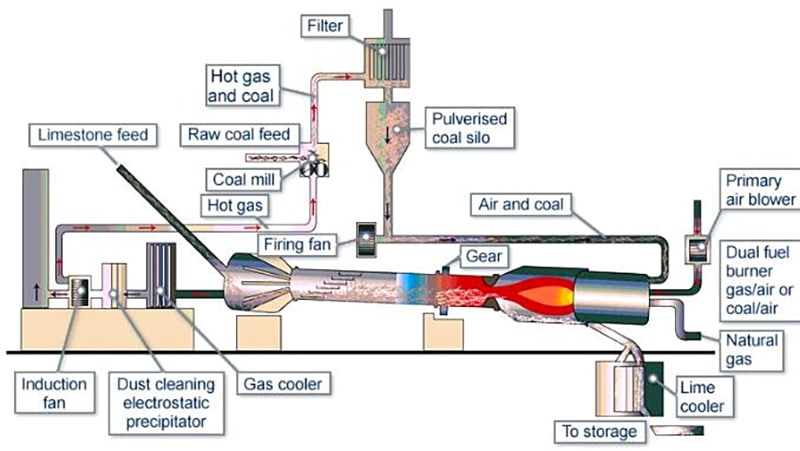

The material is fed into the kiln through the kiln tail (high end) chute. Due to the inclination and slow rotation of the cylinder, the material move from the kiln tail (high end) to the kiln head (low end); The fuel is injected into the kiln through the burner from the kiln head end (lower end) for combustion. The heat is transferred to the material ,After the material is calcined in the moving process, it is discharged from the kiln head end, and the high-temperature flue gas enters the kiln tail dust removal system from the kiln end.

Features:

Product stability: When calcining the material, the material can be heated evenly and the product quality is stable

Transmission system: The main transmission system adopts a new type of AC frequency conversion speed regulation technology, which is energy-saving and environmentally friendly

Support roller device: after vibration aging treatment to eliminate welding stress, it can improve the installation accuracy of the whole machine

Optimized structure: The overall structure is optimized to solve the common problems of kiln back material return and dust leakage