Jaw crusher

Usage and applicaton:

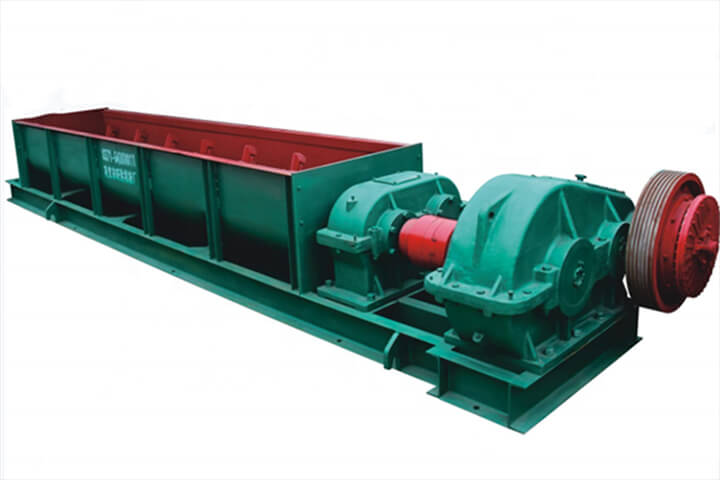

double shaft mixer price is the efficient equipment for Mixing powder materials

The double-shaft mixer is a device which uses a pair of spiral shafts with stirring blades to rotate synchronously and humidify and agitate the powdery material.

Working principle:

Horizontal barrel body with rotating reverse the blade, the pulp into a certain angle of the material along the axial, radial cycle stir, so that the material quickly mixed. It shortens the mixing period with more efficient. Even if the material has a specific gravity and difference particle size, it will also achieve a good mixing effect in the staggered arrangement of the mixing blade fast and by the violent throwing thrown.

Features

1. This double shaft mixers uses high-chromium and high-molybdenum scale boards and stirring pieces, with a long service time.

2. Shaft seal is applied with patented air pressure seal, which can effectively prevent the leakage of mortars.

3.With compacted structure. and Can be mixed liquid of 30% of the viscous material.

The dual-shaft mixer is mainly composed of a casing, a screw shaft assembly, a driving device, piping, a cover plate, a chain cover and other components. The specific structure and performance characteristics are as follows:

1. The shell is mainly composed of plate and section steel, welded and formed in the manufacturing plant, and assembled with other parts, which is the support of the double-shaft mixer. The shell is tightly sealed, and there is no phenomenon of flying ash and ash leakage.

2. The screw shaft assembly is the main component of the double-shaft mixer. Its components mainly include left and right screw shafts, bearing seats, bearing sleeves, bearing caps, gears, sprockets, oil cups, blades and other parts.

3. The water-adding and humidifying piping is mainly composed of pipes, joints and nozzles. The nozzle adopts a stainless steel atomizing cone nozzle, which is arranged above the inside of the mixer shell, and is arranged axially along the spiral axis to form a water curtain to facilitate the humidification and mixing of the material. Simple nozzle structure

Single, easy to replace, stainless steel material, anti-corrosion and durable. The moisture content of wet ash can be adjusted by operating the manual regulating valve on the water supply pipeline.

4. The cover mainly includes the left cover, the middle cover, the right cover, the hole cover and the manhole cover. There are six inspection holes on both sides of the double-shaft mixer to facilitate the operator's usual inspection and maintenance.