Jaw crusher

Usage and application:

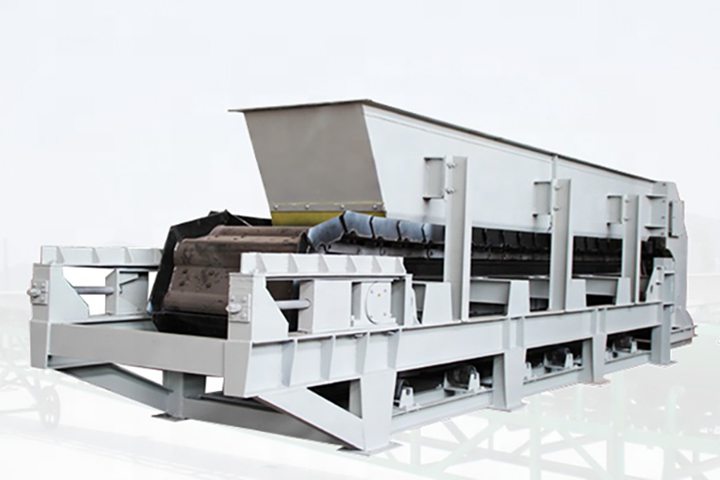

Apron feeder is a kind of conveying equipment which takes chain as traction component and chain plate as bearing component. It can convey various bulk materials along horizontal or inclined direction (inclination angle is less than 25 degrees).

Working principle:

The apron feeder consists of drive unit, frame, head device, running parts and end tension device etc. Running parts is a key of the machine. It can be dragged by circular circuit drag chain; drag chain can be traction on supporting wheel and supporting roller can support conveying channel so as to convey materials.

When the plate feeder works, the electro motor and the reducer drives the sprocket with alveolus structure to rotate, so that the hauling chain that engages with the chain wheel will drag the material trough in which there are materials to move forward. The supporting device-hauling chain moves on the thrust wheel and the riding wheel props with the conveying trough to bear the weight of the materials and the running devices. The materials are pushed from the storage bin above the tail to the conveying trough, and move along with it to the chute mouth with housing and then are discharged.

Features:

1. Wide application. It can transport materials and goods that have sharp edges. And large materials are available. It is also suitable to convey high temperature materials that are below 400℃.

2. Large carrying capacity. The slot board adopts stamping and welding structure, being able to adapt the delivery of denser materials.

3. Good airtight performance. It does not spread and leak materials during running and unloading process.

4. Smooth and reliable operation and low noise.

5. Long durability and easy maintenance.