Jaw crusher

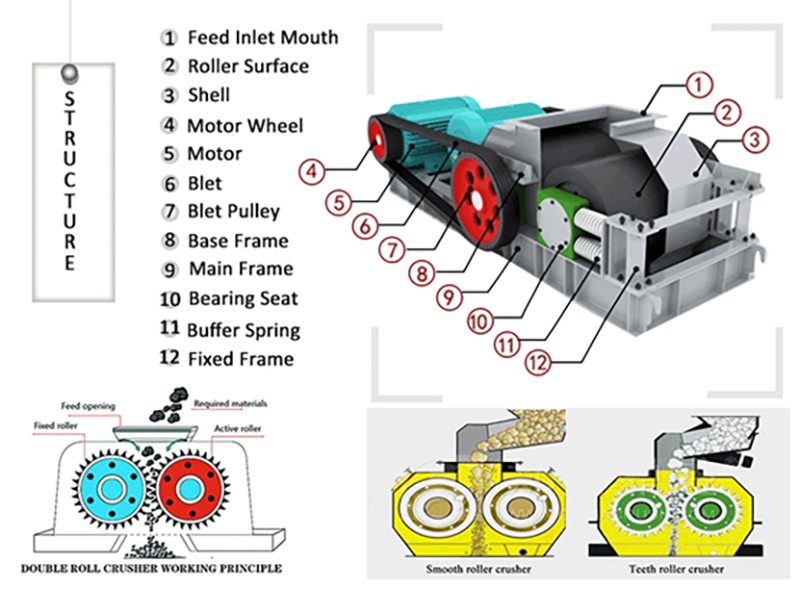

Double roller crusher usage and technical specifications:

The Doule Roller Crusher, also known as roll crusher, toothed roll crusher, is suitable for fine crush the medium hardness rock with compressive strength ≤160MPa, such as ore, rock, coke, coal, clinker, ceramic raw materials, slag, refractory materials, and chemical materials. According to the number of rolls, the roll crushers can be divided into single roll crusher, double roll crusher or, four roll crusher. Double roll crusher is the most used type. We produce industrial roller crushers and laboratory uses small roll crusher.

Working principle:

The particles are drawn into the gap between the rollers by their rotating motion and a friction angle formed between the rollers and the particle, called the nip angle. The two rollers force the particle between their rotating surface into the ever smaller gap area, and it fractures from the compressive forces presented by the rotating rollers.

Features:

1. The rollers is wear-resisting chromium molybdenum copper alloy with long service.

2. The gap between the rollers is adjustable, so that the output size and capacity will be changed accordingly.

3. This crusher is equipped with motorless scraper. When the raw material has high moisture content, it can avoid to affect the output size and avoid sticking the roller or blocking the machine.

4. According to requirement, it could be in flat roller or toothed roller.