Jaw crusher

Usage and application:

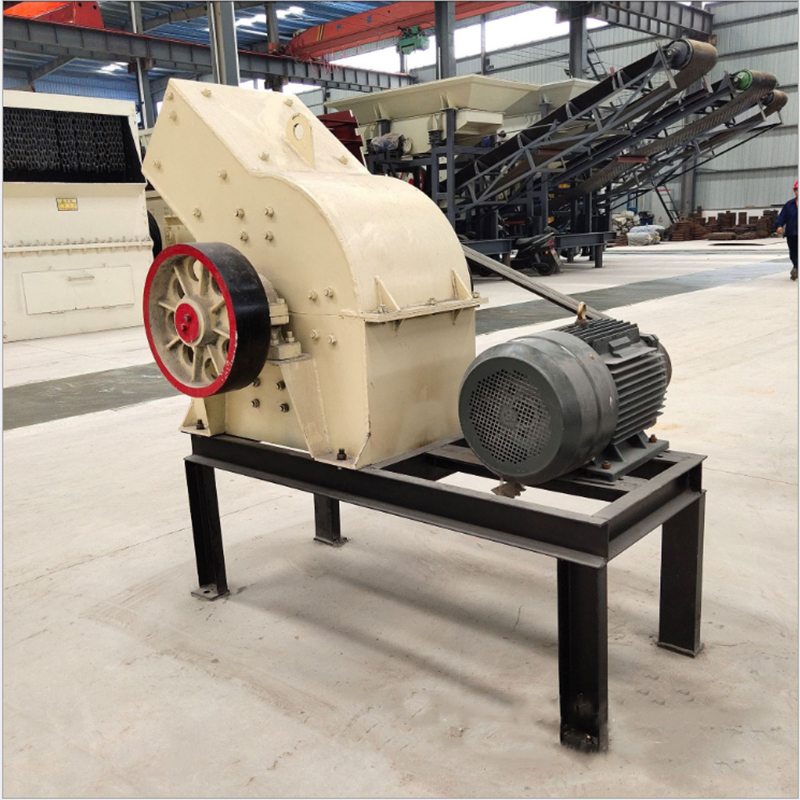

Hammer crusher is applicable for various hard and fragile materials, such as limestone, coal, salt, gypsum, alum, brick and tile, etc. The compressive strength of materials should not be in excess of 150 Mpa. Hammer crusher is mainly used in industries such as cement, coal separation, electricity generation, building materials and compound fertilizer, etc. Hammer crusher can crush materials with different sizes into equal particle, which favors the next procedure.

Working principle:

In the hammer crusher, the motor drives the rotor to rotate at a high speed through the belt, and on the rotor there are series of hammers. When the materials get into the working area of hammers, the rotating hammers with high rotation speed are crushing them; the crushed products meeting the required size can be discharged by the outlet and become the final products; the large size products are brought back to the crushing area by the hammers for being re-crushed until they reach the required sizeFeatures:

1. Advanced design technology, strong structure and impact resistance.

2. The feed size is large, the yield is high, and the grain shape is good.

3. Super crushing, coarse, medium and fine crushing in one step.

4. The year-on-year output has increased by 30%, which is more energy-efficient.

5. The hammer head and sieve plate are made of chromium-manganese alloy material, which has stronger impact resistance and wear resistance.